Join:

Join two or more parts of similar properties or totally different materials, to form a whole.

A piece that is made up of several parts can be joined by different types of joints. According to the requirement of fixation, solids or articulation, and this in turn depends on the work that must be done.

TYPES OF UNIONS

Unions Mechanical:

Made by elements that can be removed with some ease. They are very useful when carrying out maintenance on moving parts or parts subjected to a dynamic variable. As an example we have the case of speed, temperature, pressure, level, flow, etc.

They are divided into two groups, fixed unions and mobile unions:

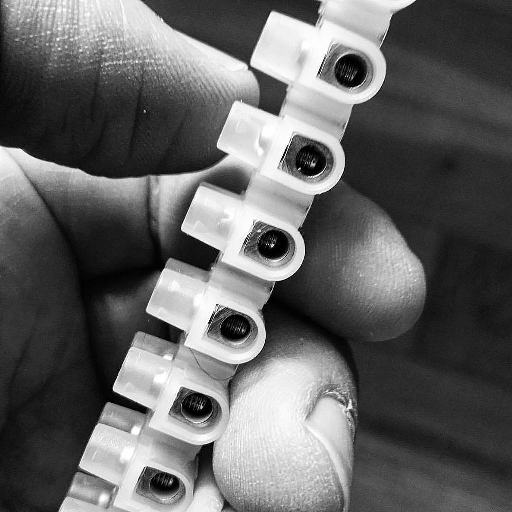

Fixed: Its purpose is to join the pieces firmly, this is the case of the screws, jaws and rivets.

Mobile: They allow a certain degree of movement between the parts that are joined, this is the case of hinges and kneecaps.

Unions Physical:

They are of the fixed type and their union is permanent. They are used to make a piece of great complexity and resistance that needs parts of different shapes and sizes. Or simply to increase the size of the element according to the requirement or specification of the project. These elements must remain firmly united.

They are usually metals or plastics, subjected to high temperatures until they reach their melting point. In some procedures there is contribution of material, this type of joints are known as welding.

There are two types of welds, depending on the temperature of the melting point of the filler material:

Soft: temperature of the melting point of the filler material of less than 450 ° C. This is the case of electric welding or electronic components with tin; used to join pieces of copper.

Hard: temperature of the melting point of the filler material greater than 450º C. As an example we can mention the submerged Arc or Electrode welding, the MIG and the TIG. They are used to join ferrous materials such as steel.

Unions Chemicals:

They are also of the fixed type. They are usually used to join materials of different physical properties or of the same elements, where the 2 types of joints previously analyzed can not be made, by the type of finish, volume, additional weight, type of material, among other reasons.

Advantage

- Low cost

- Easy application

- Hardness and resistance to the type of work where you intend to apply.

- Speed

The most common materials to use this type of joints are: cardboard, plastic, wood, glass, aluminum, porcelain.

This classification is covered by glue. Some adhesives need catalysts such as temperature, water, or other types of chemicals. Below I make a list of the type of existing adhesives:

Wet adhesives

Contact

Reactive glue

One component reactive glue

Two-component reactive glue

Hot melt adhesives

Self-adhesive

For more information about this type of glues consulthttp://www.uhu.com/es/consejos-de-pegado/tecnicas-de-pegado/los-tipos-de-pegamento.html

Leave a Reply